Nowadays, people’s lives are increasingly inseparable from electronic devices. The popularity of devices such as flashlights, 收音机, 电动玩具, 数码产品, and remote controls has led to an increasing use of batteries.

同时, with the popularity of electronic devices and the development of their functions, people’s requirements for battery performance are also getting higher and higher. To meet the needs of electronic devices for high-power discharge performance of batteries, alkaline batteries need to improve their discharge performance.

There are many ways to improve the discharge performance of alkaline batteries. This post will discuss the two aspects of the improvement of negative electrode materials and separators.

Optimizing battery separators

The separator is one of the components of the alkaline battery. On the one hand, it can separate the active materials of the positive and negative electrodes inside the battery to avoid short circuit of the battery. On the other hand, it can conduct the movement of ions inside the battery.

We know that the process of battery discharge is the process of ions moving between the positive and negative electrodes inside the battery. There are tiny holes in the separator through which ions move between the positive and negative electrodes. 所以, the size and porosity of the holes in the separator affect the speed of ion transfer and the internal resistance of the battery during battery discharge, thereby ultimately affecting the discharge performance of the battery.

Improving porosity and increasing the pore size of the separator can provide a faster channel for ion migration, and the internal resistance of the battery is smaller, thereby greatly improving the high-current discharge performance of alkaline batteries.

然而, it should be noted that the increase in porosity and the increase in pore size may cause the active materials of the positive and negative electrodes inside the battery to directly contact and cause a battery short circuit. 所以, optimizing battery separators requires comprehensive consideration of both positive and negative consequences to find a balance and optimal solution.

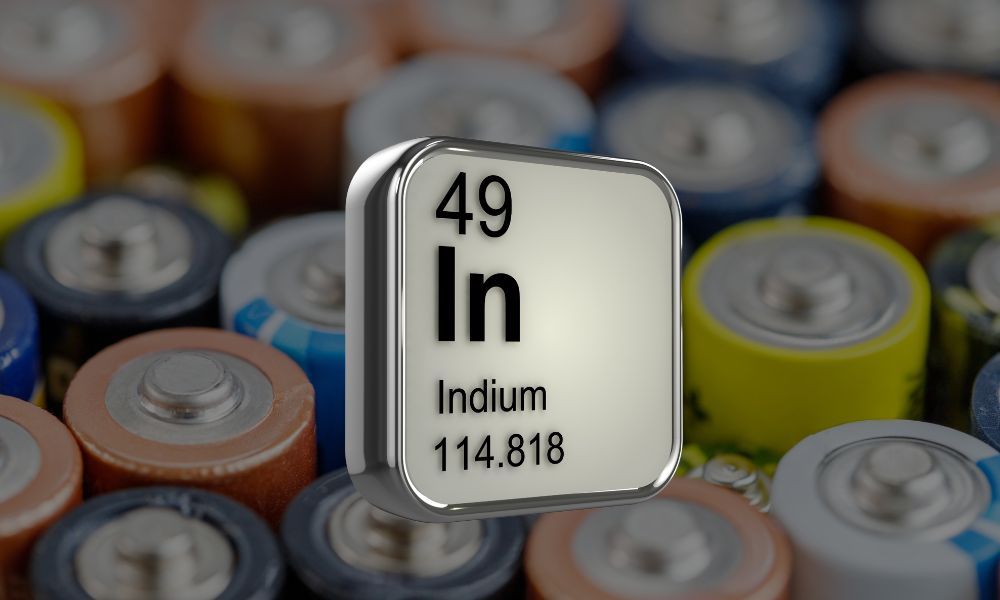

Optimizing negative electrode materials

The negative electrode material of alkaline batteries is zinc powder. The finer the particles of zinc powder, the larger the contact area for chemical reactions and the greater the current density. 所以, the potential of the battery’s high-current discharge performance will be more easily and completely released.

Some researchers have conducted experiments and added some finer zinc powder particles to the negative electrode material of alkaline batteries, and the high-current and high-power discharge performance of the battery has been significantly improved.

然而, the electrolyte in alkaline batteries has a certain corrosive effect on zinc powder. If the zinc powder is too fine, it may be corroded faster, causing battery leakage. 所以, when using fine zinc powder, a corrosion inhibitor needs to be added to the negative electrode to inhibit the zinc powder from being corroded.

To summarize the above, we know that the use of separators with high porosity and large pores that can prevent the positive and negative active materials from contacting each other, finer zinc powder, and corrosion inhibition that can inhibit the corrosion of fine zinc powder in alkaline electrolyte Agent is of great significance to improve the high power discharge performance of alkaline zinc-manganese batteries.